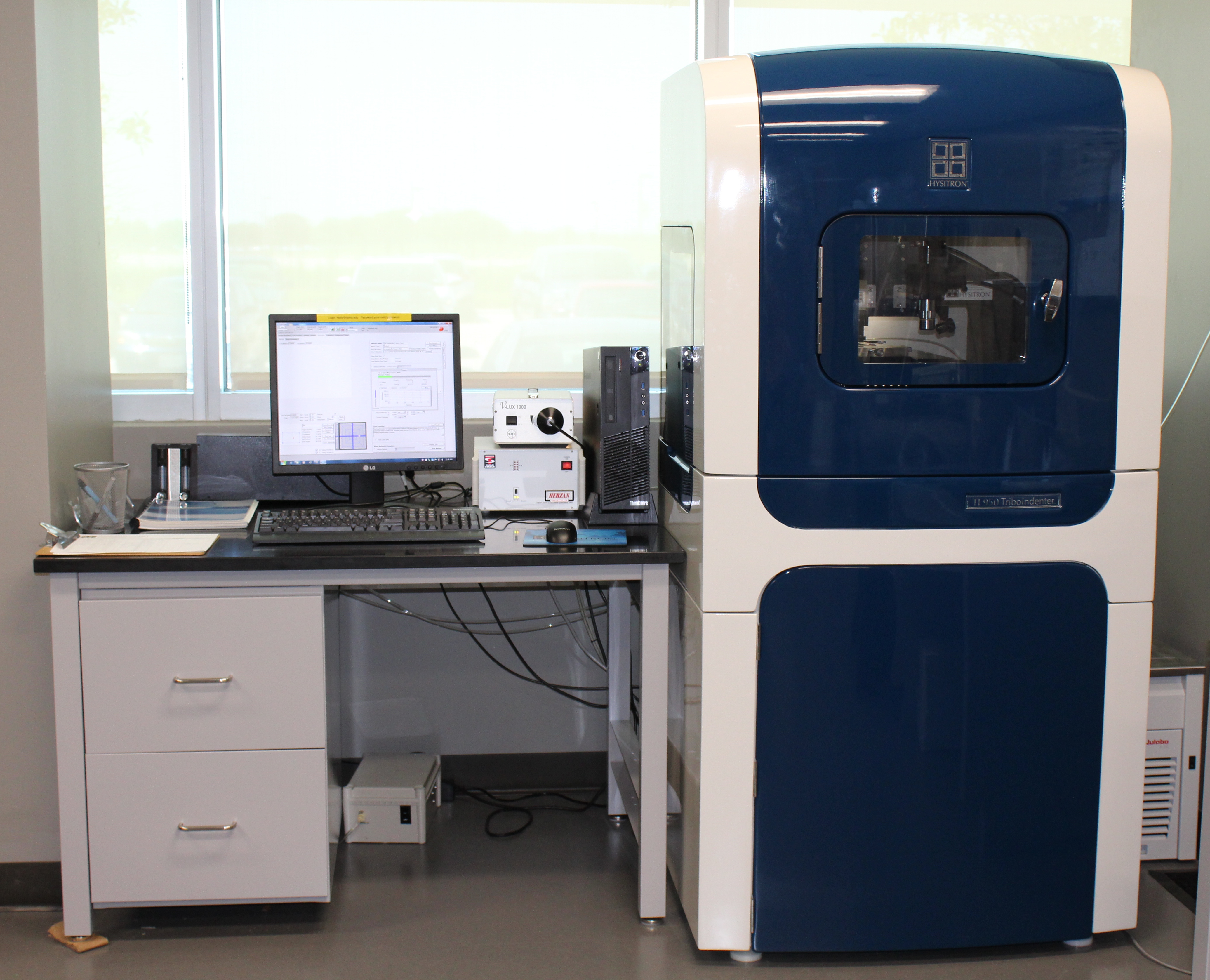

The Hysitron TI 950 Triboindenter is a nanomechanical test instrument ideal for measuring the hardness and elastic modulus of materials. The Hysitron TI 950 Triboindenter is equipped with automated X, Y and Z staging system as well as Z piezo for positioning and SPM imaging. The TI 950 Triboindenter is equipped with performechAdvanced Control Module which provides great performance for nanomechanical testing. With dual head systems incorporated, the TI 950 nanoindenter enables testing at the nano/micro scale levels.

For more information about the Hysitron Triboindenter, go to www.hysitron.com

TI 950 Triboindenter Features:

- Dual head testing for low load and high load performance

- Integrated temperature and humidity sensor

- Improved lateral measurements for thin film samples

- Automated testing for high throughput

- In-situ SPM imaging to obtain topography and precise sample positioning

- Acoustic and thermal enclosure for environmental stability

- Top-down optics for viewing the samples

- Active vibration isolation system for dampening of noise

TI 950 Testing Modes:

- Quasistatic Nanoindentation – Measures Young’s modulus, hardness, fracture toughness and other mechanical properties via indentation

- Scratch and wear testing – Quantify scratch resistance, critical delamination forces, friction coefficients and wear volumes

- Top-down optics – Color CCD camera for identification of sample locations for testing.

- SPM imaging – In-situ imaging using the indenter tip enables nanometer precision positioning, SPM topography and gradient views

- Fluorescence microscope – Fluorescence microscope option replaces the standard optics column. TI 950 Triboindenter instrument is capable of performing both standard bright-field and fluorescence imaging.

- NanoDMA and Modulus Mapping – Quantitative measurements of viscoelastic nanomechanical properties from the in situ SPM imaging.

- TriboEA – Acoustic emission signals from fracture or deformation

- xSol high temperature stage – The thermally stable xSol stage design provides feedback-controlled temperature accuracy during high temperature (800 ᵒC) testing.

- xZ 500 Extended Displacement stage – Suited for testing adhesive and compliant samples. Displacement up to 500 µM is obtained.

To be trained on this instrument, please contact Dr. Wilson Serem.

Specifications

Transducer

Load

- Resolution: <1 nN

- Noise Floor: 100 nN

Displacement

- Resolution: 0.0004 nm

- Noise Floor: 0.2 nm

- Drift: <0.05 nm/sec

Stage

X and Y stages

- Travel: 250 mm x 150 mm

- Encoder Resolution: 500 nm

Z stage

- Travel: 50 mm

- Resolution: 3 nm